Isevisi ye-Medical PCB Assembly

Isingeniso Sesevisi

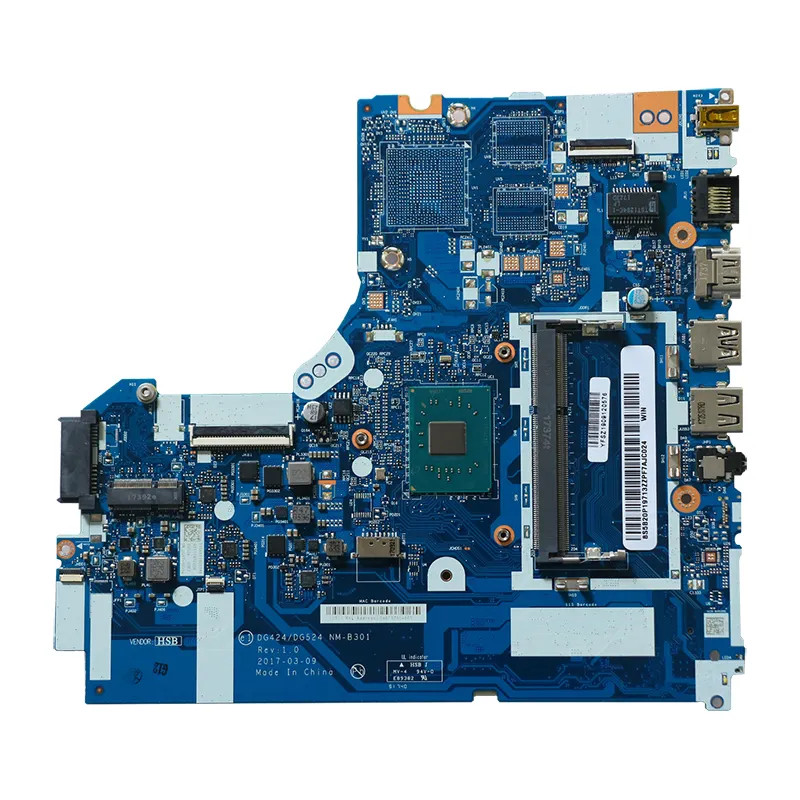

Ukuhlanganiswa kwama-PCB ensiza yezokwelapha kudinga ukubambelela ngokuqinile kumazinga nemithethonqubo yekhwalithi ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana nezimfuneko ezidingekayo futhi uphephile ukusetshenziswa ezinhlelweni zezokwelapha. Ngendlela yethu yokulawula ikhwalithi, sibhekana nanoma iyiphi ingozi ehlobene ne-PCB yedivayisi yezokwelapha ukuze siqinisekise inqubo yokukhiqiza engenazihibe kanye nokusebenza kwedivayisi kukonke.

Uma unezidingo ze-Medical PCBA, sicela usithinte futhi uhlole izinsizakalo esizihlinzekayo:

• I-Multiple PCB Assembly: SMT, THT, Mixed Assembly, Package on Package, Rigid/Flex PCBs, njll.

• Ezinye izindlela zokuhlanganisa ivolumu eguquguqukayo: Ama-prototypes, ivolumu ephansi, ivolumu ephezulu.

• Ukuthola izingxenye: Ukusebenzisana nabakhiqizi nabasabalalisi bezingxenye ze-elekthronikhi abagunyaziwe.

• Ukuqinisekisa Ikhwalithi Ephelele: ukuhlolwa okuqinile kokusebenza kanye nekhwalithi.

• Ithimba Lonjiniyela Abaqeqeshiwe: Siqeqesheke kakhulu futhi sizinikele empumelelweni yephrojekthi yakho, okukuvumela ukuthi uqale ngamadizayini athuthukisiwe futhi sikunikeze ithuba elingcono lokufeza umnqamulajuqu wephrojekthi.

Amandla Okukhiqiza

Amakhono Ethu Esevisi Yezempilo Ye-PCBA

| Uhlobo Lomhlangano | Uhlangothi olulodwa, olunezingxenye ohlangothini olulodwa lwebhodi kuphela, noma olunezinhlangothi ezimbili, ezinezingxenye zombili izinhlangothi.

I-Multilayer, enama-PCB amaningi aqoqwe futhi ahlanganiswa ndawonye ukuze akhe iyunithi eyodwa. |

| I-Mounting Technologies | I-Surface mount (SMT), ipuletiwe ngembobo (PTH), noma kokubili. |

| Amasu Okuhlola | I-PCBA yezokwelapha idinga ukunemba nokuphelela. Ukuhlola nokuhlola kwe-PCB kwenziwa ithimba lethu lochwepheshe abanolwazi ekuhloleni nasekuhloleni amasu ahlukahlukene, okusivumela ukuba sibambe noma yiziphi izinkinga ezingaba khona phakathi nenqubo yomhlangano ngaphambi kokuba zibangele izinkinga ezinkulu emgwaqeni. |

| Izinqubo Zokuhlola | Ukuhlola okubonakalayo, Ukuhlolwa kwe-X-ray, i-AOI (Ukuhlola Okuzenzakalelayo Kokuhlola), I-ICT (Ukuhlolwa Komjikelezo) , Ukuhlola okusebenzayo |

| Izindlela Zokuhlola | Ekuhlolweni Kwenqubo, Ukuhlolwa Kokwethembeka, Ukuhlolwa Okusebenzayo, Ukuhlolwa Kwesoftware |

| Isevisi ye-One-Stop | Idizayini, Iphrojekthi, Ukuthola, i-SMT, i-COB, i-PTH, i-Wave Solder, Ukuhlola, Ukuhlanganisa, Ezokuthutha |

| Enye Isevisi | Idizayini Yomkhiqizo, Ukuthuthukiswa Kobunjiniyela, Ukuthengwa Kwezingxenye Nokuphathwa Kwezinto, Ukukhiqiza Okunciphile, Ukuhlola, Nokuphathwa Kwekhwalithi. |

| Isitifiketi | ISO9001:2015, ISO14001:2015, ISO45001:2018, ISO13485:2016, IATF16949:2016 |